carrageenan production process

04 Programs Shared Service Facilities SSF Project. Carrageenan is an approved food additive.

Production process for semi-refined carrageenan is always the same.

. The production and manufacture of export products covers the productionmanufacture of non-traditional export products and with export requirement of at least 50 of its output if Filipino-owned or at least 70 if foreign-owned. κ-carrageenan solution is introduced in 1 L bottle C maintained at 70 C. Alkali treatment and extraction After the seaweed has been cleaned it is heated with water containing an alkali for several hours.

Carrageenan is an important production used in the cosmetic industry because of its physical and functional ability and antioxidant activity. Carrageenan is a well-known gelling agent used in the food industry. Then the sifting process which is to remove any sand that carried on the raw material accidentally.

To do it the caraageenan factory will use freeze-thaw method which will pour the solution through small holes to be mixed with potassium chloride solution. The first step in the production process is the cleaning and washing. After harvest the seaweed is dried baled and sent to the carrageenan manufacturer.

In this process seaweed is chopped and washed. IOTA elastic gel thermo-reversible no syneresis thixotropic. The gel-press process used by some minor producers of carrageenans and agar likewise relies on pressure to dewater the gel but omits the freeze-thaw cycle.

Carrageenan also offers some in-process advantages because it has a comparatively low viscosity in solution before it gels. The economics of extraction processes are strongly affected by the cost of the energy required to bring the carrageenan into solution and subsequently to recover it in dry form. After treatment with hot alkali solution eg 58 potassium hydroxide the cellulose is removed from the carrageenan by centrifugation and filtration.

This step is necessary to remove any foreign material such as sand salts sticks and any debris which may appear naturally with the seaweed. For refined carrageenan there are three methods used in the industry. This will result in spaghetti like carrageenan which still needs to be washed using potassium chloride solution and pressed to eliminate the water content before being frozen.

In the original method - the only one used until the late 1970s-early 1980s - the carrageenan is extracted from the seaweed into an aqueous solution the seaweed residue is removed by filtration and then the carrageenan is recovered from the solution eventually as a dry solid containing little else than carrageenan. There the seaweed is ground sifted to remove impurities such as sand and washed thoroughly. It is based on the latest economic data and presents exhaustive insights about the primary process flow raw material requirements reactions involved utility costs operating costs capital investments pricing margins etc.

First process that the factory will do is the grinding process to make the raw material which is the kappa carrageenan itself becomes easier to be processed. Semi Refined Standard Method Refined by Drum Drying Refined by Alcohol Precipitation Refined by Gel Press Properties 1. The report provides the economics of Carrageenan production starting from seaweed using a batch extraction process in the presence of calcium hydroxide.

The bottle is placed under pressure controlled by a manometer B leading to solution extrusion dropwise through a nozzle D. Carrageenan has found an interesting use as an effective lubricant during sex. The study covers all the requisite aspects that one needs to know while making a foray into the carrageenan industry.

The gel-strength- ening properties of carrageenan are as a result of the fairly strong bonds it forms with casein macromolecules. In addition to reducing friction in sensitive areas it has anti-microbial and antiviral properties and is an effective carrier for anti-retroviral drugs in HIV prevention and treatment. In a flan product carrageenan will form the necessary gel structure control the basic product texture react with and stabilize the milk protein provide uniform stabilization and improve flavor release.

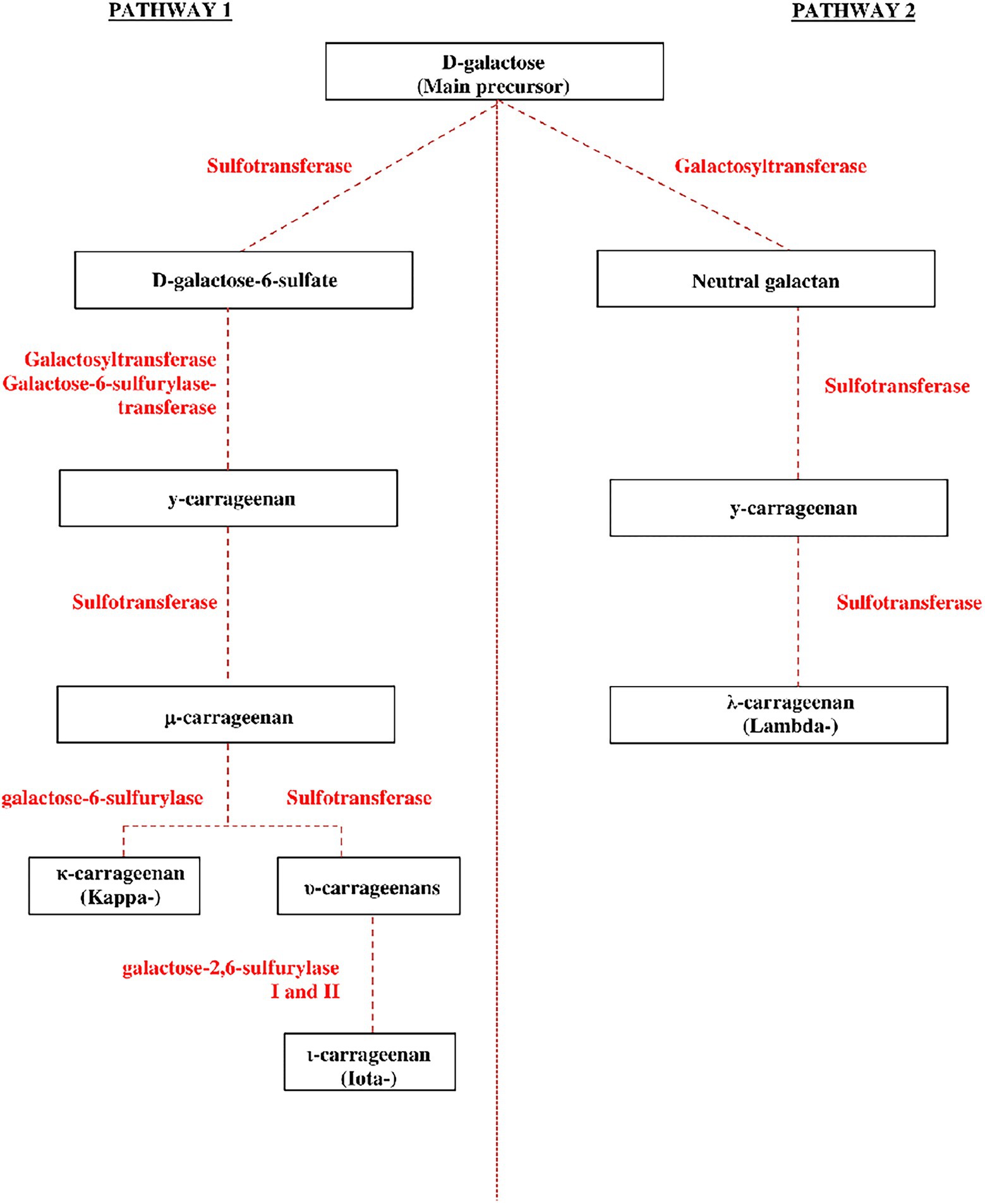

Cargill offers one of the widest ranges of commercially available carrageenan employing proven production processes and using a large variety of different types of red seaweeds Rhodophyceae from the Gigartinales group. Carrageenan can be classified according to its structure and chemical properties or according to its production process. Carrageenan synthesis by the treatment of OH from red algae.

To ensure sustainable sourcing of our offer Cargill has established the Red Seaweed Promise. Drum Drying Alcohol Precipitation and Gel Press. Of course washing process is done to completely remove other impurities.

Most of the carrageenan derivatives consider for cosmeceutical production and isolated from red seaweeds. Shortages of carrageenan-producing. Then Carrageenan is batch extracted in the presence of calcium hydroxide into an aqueous solution.

Structure and Chemical Property KAPPA rigid and brittle gel thermo-reversible high gel strength showing syneresis. The present review of patent and scien- tific literature shows that carrageenan is a useful additive in the cheese production process. Experimental Set-Up and Bead Production Figure 1 The experimental set-up for producing κ-carrageenan beads is presented in Figure 1.

Proposed Carrageenan Biosynthesis Pathways Pathway 1 Download Scientific Diagram

Characteristics Of Lactose Free Frozen Yogurt With K Carrageenan And Corn Starch As Stabilizers Journal Of Dairy Science

Seaplant Net The South East Asia Seaplant Network

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Carrageenan Foods Additives Is Carrageenan Safe

Basic Carrageenan Forms Iota I Kappa K Lambda L Mu M Nu Download Scientific Diagram

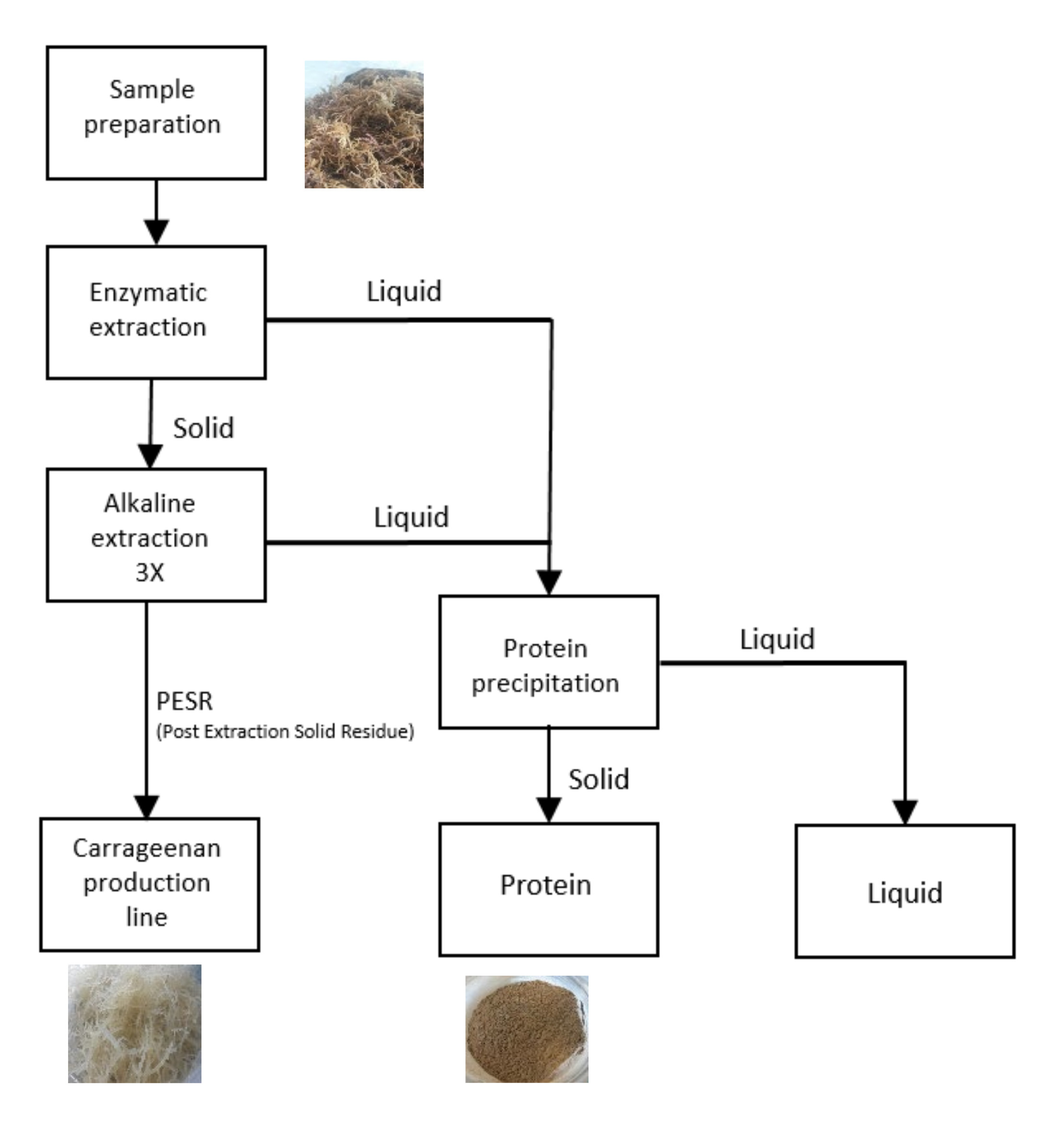

5 Flow Chart Of Semi Refi Ned Carrageenan Production Where The Download Scientific Diagram

Re Evaluation Of Carrageenan E 407 And Processed Eucheuma Seaweed E 407a As Food Additives 2018 Efsa Journal Wiley Online Library

Foods Free Full Text Multi Extraction And Quality Of Protein And Carrageenan From Commercial Spinosum Eucheuma Denticulatum Html

Conventional Extraction Method Of Refined Carrageenan Rc And Download Scientific Diagram

Frontiers Carrageenan From Kappaphycus Alvarezii Rhodophyta Solieriaceae Metabolism Structure Production And Application

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Pdf Extraction And Isolation Of Kappa Carrageenan From Red Seaweeds Semantic Scholar

Carrageenan Production Methods

Process Flow Sheet For Preparation Of Semi Refined Carrageenan Download Scientific Diagram

Lecture Xviii Charged Ps S Carrageenan Agar Ppt Download

Carrageenan 101 Mcpi Carrageenan For The World

0 Response to "carrageenan production process"

Post a Comment